How It’s Made: Firearm Restoration at Brubaker Arms Manufacturing, LLC - Restorations Department

- bryan457

- Mar 24, 2023

- 13 min read

There is little limit to the possibilities of custom metal and wood work for your firearm.

We are a fully equipped, self-standing 3200 sqf gumnaking / gunsmithing shop, located in the heart of Washington State. We offer the possibility to discuss your custom project without having to deal with the inconvenience of retail traffic. Today, we'd like to share with you the process your firearm goes through when we start a restoration or a custom made project.

DIAGNOSTIC CLEAN (DCOA)

Mechanical Work: Safety First!

We first completely disassemble the firearm and evaluate every part. Everything is cleaned up nicely and prepared for polishing and refinishing. The parts that need to be addressed are either replaced or fixed (if safe); if unavailable, we will manufacture the parts for you. Our master gunsmiths can reverse-engineer obsolete parts for antique firearms or for contemporary firearms that are no longer manufactured, and in general any parts that are no longer available on the market.

WOOD WORK

The Value Of A Custom Fitted Wooden Pattern

One of the main differences between Brubaker Arms Manufacturing LLC custom stocks and other gun restoration companies is that our restoration department at Brubaker Arms offers the option to have a custom pattern made, which can then be replicated in any number of blanks of your choice.

A standard factory production stock and a factory stock template are made to a set of dimensions that would loosely fit most shooters, and would render a stock that is easy and economical to produce commercially. A custom fitted stock is tailored to the specific dimensions of the individual. That way, the shooter doesn't need to twist their body to line the eye behind the sights, but when the firearm is thrown up to the shoulder, the sights are in perfect line in front of the eye. This eliminates the few very important seconds that are usually wasted on adjusting the eye line behind the scope; sometimes all you have is that split second before the deer runs away or before the other competitor wins the match. In other words, the line of sight and the point of aim are matched in the geometry of the firearm - and the custom stock plays the essential role in this.

We do not generally recommend the use of wooden templates that are dimensioned to fit an average shooter, but we encourage the production of a one-of-a-kind stock template for each customer. Some customers prefer to leave their templates with us, in order to be able to duplicate additional stocks for other shotguns and even rifles (with minimal changes). Other customers prefer to have their templates in possession, in which case we can have them shipped together with the firearm. At any rate, a custom fitted stock can be replicated way easier if a custom pattern is produced first. If the budget calls for a lower grade stock, we make available the option to skip the template production and produce a one-off custom stock.

The cost of producing a one-off custom stock is lower than the cost of producing a template and then duplicating it, for obvious reasons. However, the investment in a custom stock template is definitely worth it, especially for trap shooters who like to own and use different firearms by rotation. Having a custom wood template actually saves a lot of fitting time (and money) because the cost of measuring and fitting any additional stocks for other firearms that fit the owner perfectly is reduced to zero; the only cost left is the actual cost of duplicating.

At the same time, it allows for testing before having a precious piece of wood carved and shaped. (Once that file goes in, there’s no way to add the wood back!)

In general, if the original stock is not made out of a precious piece of wood, it will be used as starting point for building a custom pattern that fits the customer like a glove. The original stock is re-shaped to fit the particular measurements of the owner by adding a patching compound where it needs it and by filing down the areas that need to be removed. The advantage of using the original gun stock for producing the template is that the original gun stock is already fitted to the action, so there’s no inletting necessary. Once the pattern is produced, it is installed on the firearm, and the firearm owner gets the chance to shoot the firearm and test the ergonomics of the stock. We prefer it when one of our gunsmiths has the opportunity to join the customer at the range / at the club, and has the opportunity to make on the spot the adjustments necessary to the fitted gun stock. That way, any adjustments that need to be made are addressed prior to the pattern being duplicated into a precious piece of wood.

The custom gun stock template silhouette is then traced on the blank of choice (we usually use Turkish walnut imports or well dried American walnut). In order to allow for manual tolerances and a comfortable final shaping, we leave a margin of roughly 1 inch wide around the shape of the pattern. We rough-shape the stock and remove all excess wood, as we prepare the blank for duplicating. Our band saws are calibrated to the ideal speed for cutting through various types and grades of wood. Throughout the years, we have worked with olive wood, rosewood, Circassian, Claro, American and Turkish walnut, with different grains; the more attractive the figure, the more careful we need to be when we rough shape and finish the wood. The grain and the wood grade make a difference in the amount of time needed to work with the wood.

In order to duplicate a pattern, we use one of our two wood stock duplicators, depending on the quantity of stocks that we are producing. At Brubaker Arms Manufacturing, we operate two wood stock duplicators: a large six station Salstorm duplicator – when we are producing a number of stocks for our customers – and a one stock duplicator for one-off orders.

Both our duplicators use the standard stylus – rotary head type, but allow for multiple rotary head sizes types, depending on the quality and figure of the wood that we work with. The stylus traces the shape of the custom template, and directs the router’s cuts into the piece/s of wood, which is why it’s important to make sure that we use the right rotary shape and size. The duplicating process is a labor intensive process, but it is considerably faster when using the right duplicator.

The next stage is the inletting. If the customer ordered the stocks as a semi-inlet, we stop at 95%-98% inlet. If the customer works with us on a full restoration or stock replacement, we will fit the gun stock to the action entirely. All our inletting is done manually, using inletting black and gold, which mark the areas that need to be filed down in order for the stock to fit the action perfectly. This type of manual inletting is a time consuming process, but it is the only way to make sure the wood and the metal work together in harmony. Below, an example of a very complex manual inlet that we produced for a Bond.

During the inletting stage, after the stock is completely fitted to the action, we manually finish using different files and sanding paper grains. From the time the stock leaves the duplicator, all other shaping and fitting are done manually - from filing down the rough patches left by the duplicator, to rough sanding paper and to fine sanding paper, until the stock is perfectly smooth and ready to have the stain and finish applied. When it comes to wood finishes, we offer a number of options: lacquer (for the budget options), oil (in-house boiled or commercially boiled), and a high-end two-part epoxy finish, similar to the Weatherby original finish. The original Weatherby finish is no longer available on the market, but what we use is a special two part varnish that is primarily developed for the marine industry, for sealing masts and staves and other parts that are exposed to the caustic marine environment. It is a very durable finish. A high-end finish helps the grain and figure of the wood show. If the customer asks for a stain to be used – or when restoring the firearm to the appropriate era requires a particular type of stain – we will do so; we use high-end stains that preserve their color in time and do not react with the oil or the two part varnish finish that we apply after the stain is dry. We even produce a number of them in house.

The checkering stage is one of the most skill-requiring stages in producing a custom stock for a shotgun or a rifle. We like to have the customers involved at this stage, by inviting them to select what type of patterns they prefer. Checkering is usually re-cut era-accurate for restorations of firearms, but it can also make room for the creativity of the gunmaker / client when an era-accurate checkering is not required. Our gunmakers and gunsmiths are proficient in producing pointed checkering, English flattop checkering, semiflattop checkering, fish scale checkering, borderless checkering, fill in checkering, fancy checkering, angular patterns and wrap around patterns. Checkering ads visual interest and gives the rifle or the shotgun a better grip. The art of vintage gun restoration includes a fair amount of knowledge and know-how of various checkering styles, especially when an era-accurate style is required.

The interesting part when it comes to wood restoration is that when a nice stock is put against aged metal, the metal will look particularly bad if the wear and tear of the last decades is not addressed. The brand new, fresh wood, will underline the metal wear. So while one of our gun makers is focusing on the wood, another gunsmith will be focusing on the metal, and prepare it for refinishing and engraving.

METAL WORK The Proof is in the Metal Preparation! Metal refinishing has to do with two components: metal texture and metal finish.

Preparing the metal for refinishing: This part of the process is the most important part of refinishing the metal. The original finish is carefully removed; all pitting and rust are removed as well, and all machining marks are corrected with hand-polish. This polishing process can take as little as 5 hours for firearms that have no rust or pitting, and as long as 25 hours for rifles that are very rusty. The average time is between 10-15 hours of hand polishing for all machining marks to be removed.

The texture of the metal has to do with the level of polish and gloss that metal is prepared to. At Brubaker Arms Manufacturing, LLC we offer five types of different metal textures, each one great for replicating a particular era; for newer firearms, the metal texture choice depends on the intended purpose of the firearm and the desired finish.

Brubaker Arms features the following metal textures:

- matte texture (abrasive / bead blast / wire wheel followed with all screw holes and corners protected and square);

- satin texture (abrasive / bead blast / wire wheel followed with all screw holes and corners protected and square. Finished with Scotch-Brite.)

- semi-gloss (polished to #320-#450 grit polish with all screw holes and corners protected and square. Finished with Scotch-Brite.)

- high-gloss (polished to #600 grit polish with all screw holes and corners protected and square. Finished with Scotch-Brite.)

- mirror (polished to #1500 grit polish with all screw holes and corners protected and square; all polishing marks removed, no ripples, and finished with #1500 polish to a mirror finish. Finished with Scotch-Brite.); when paired with Charcoal Bluing, this metal texture will replicate the Traditional Colt Bluing, which we really love on Colt Pythons.

Once the rust and pitting are removed, the metal is bead blasted, polished and prepared for finishing. In our experience, a long gun that has average wear (the rust is not too dramatic and there is no pitting – the wear is more of a normal wear-off of the bluing), requires a minimum of 10 hours of polishing, but usually the long guns that come through our shop require about 12-15 hours of manual polishing as most long guns have at least some minimal rust. This leaves the metal in a condition that we call “better than original”.

At this stage, after the metal has been polished to the right grit, and the rust, pitting and machining marks have been removed, we usually have a conversation with the customer about the engraving.

New engraving is a fairly direct process; the desired design is discussed with the customer, and decided based on factors like manufacturer, era of manufacturing and personal preference. Elaborate engravings on the rifle / shotgun receiver aren't necessary, but they can make an old rifle look really upscale. It's up to the client to decide if they want to keep it simple or go with a fancy restoration process, which is by no means cheap but it also doesn’t look cheap.

Sometimes we engrave a gun’s receiver with scrollwork or other era accurate designs; other times, we do gold inlay or bonanza gold. Our engravers cut the steel entirely by hand for all classic engraving orders. We do offer the option for laser engraving, but not for old classic firearms.

With either one of the engraving types that we offer (hand cut or laser cut), there's no room for error because a mistake can't be corrected.

However, something that we take pride with here at Brubaker Arms Manufacturing, LLC, is the engraving restoration process that we have developed in-house.

Using CAD design software, we are able to scan the existing engraving pattern on any given firearm. The parts that wore off completely can then be re-composed and re-designed. We start with a complete historical analysis of what is left of the engraving that wore off – we study the typology, the line style, and compare it to similar examples from our archives. We do a photographic analysis of the object to restore, a complete pattern analysis; we then conduct measurements and reconstruction on the leftover traces of the engraving.

Next, we hand sketch the computer generated patterns on the metal to engrave. We scale the pattern and re-compose it according to the surviving traces on the object to restore. We then do a final sketch, transpose the pattern to the area to be engraved, and we proceed with the actual engraving.

This process, that has been established in house by our restoration specialist, is making the most of the new technologies that we have available at hand (AI, CAD software, digital scanning, digital photography, etc.), and the traditional hand cut engraving skill.

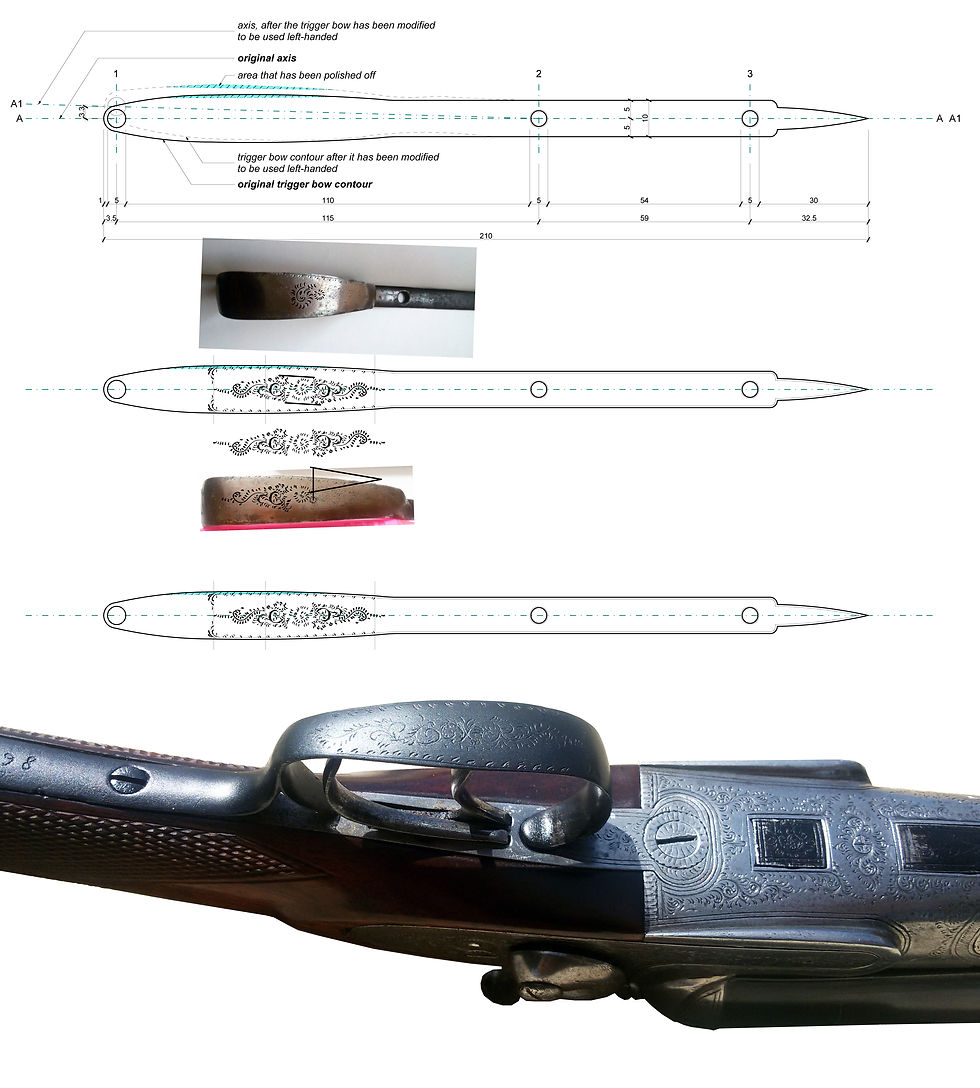

Below, a prime example of a very successful engraving restoration conducted by Brubaker Arms on the trigger bow of a 1899 field-grade W.R. Pape. The trigger bow had been modified to fit a left handed shooter. A small part of the trigger bow had been polished off, and the axis had been modified to fit the ergonomics of the left hand. In the meanwhile, the engraving wore off, and when we restored the entire firearm, we were tasked with restoring the engraving to the original condition, and re-blue the trigger guard.

After the engraving is done, or if the engraving is all together skipped, our gunmakers offer eight types of finishes and three types of coatings that can be applied to firearms. Of course, not all these finishes or coatings are recommended for any type of firearm, and sometimes we will refuse to fulfill a particular type of request – for instance, we will refuse a request to Cerakote a classic English gun like a Webley & Scott (not that many W&S owners would ask for having their M700 cerakoted, but sometimes fine guns do fall in the hands of those who don’t know exactly what they have).

The metal finishes that our shop offers are:

- Caustic Salt Bluing – which is the industrial process of bluing firearms, used by most manufacturers on a large scale; this type of bluing is also known as hot bluing, salt bluing or Oxynate bluing; this finish cannot be done on firearms that have soldered ribs. This finish usually lasts about a decade on long guns with average use.

- Slow Rust Bluing – which is the original, most time-demanding and perfected way of bluing metal; it is a one-week long process that produces a thicker coat of rust, which can be performed on rifles / shotguns that have soldered parts and ribs; this finish usually lasts 20-30 years on long guns with average use.

- Slow Rust Browning is similar to Slow Rust Bluing – the only difference is that the color of the rust will be different.

- Belgian Bluing (Express Bluing) – is an expedited process of Slow Rust Bluing, and the finish that results lasts about 15 years on long guns with average use;

- Nitre Bluing or Fire Bluing – we offer it for small parts / accessories only;

- Anodizing – offered for aluminum only

- Color Case Hardening – We use the traditional wood and bone charcoal method of color case hardening (pack hardening).The process results in a marbleized coloring of the parts and provides a thin hardened layer of steel while preserving a softer steel core;

- Charcoal Bluing - a hard-wearing finish with colors that vary from a blue-black (when the metal is polished to mirror) to a lighter blue (if the metal is polished to a lesser grit / less polished).

WRAPPING UP AND TESTING: Once the firearm had been tested for any mechanical issues, had been polished and refinished, the checkering and the engraving have been recut, it is time for the final skill test: the re-assembly. This is another underestimated part of a project, but during the process of final assembly a number of things can go wrong, like the finishes being marred or the checkering getting scratches. Not at our shop, tho! Our gunsmiths are carefully assembling each part, making sure everything fits in just as designed. Sometimes four hands are needed for a successful assembly; in that case, we will assign two gunsmiths to work on reassembling your firearm.

After assembly, we will fire and hand-cycle the firearm. We will also run the drop-test, to make sure the firearm is safe to carry. We record all testings, so we can provide the testing footage at request. We are equipped with a testing booth, so the firearms are tested on premises.

INVESTMENT:

In our experience, an average long gun restoration costs around $3500-$4000, when there is no major mechanical work required on the functioning side of the firearm, and when there are no major issues to address (like cracks in the wood, pitting, rust, broken or missing or loose parts, the stock is not replaced with a custom fitted stock, etc.). The price can escalate quite significantly with expensive engravings and gold inlay work or a custom fitted stock, or if there are any mechanical malfunctions that our gunsmiths need to address. A custom fitted new stock and engraving restoration / fresh engraving will up the price of restoration towards $10,000. This is actually a very affordable cost, depending on the cost of the firearm and the overall value of the firearm. Most firearms that go through a 10k re-do are worth anywhere between 20-50k; a massive overhaul is only needed once every two decades or so, provided the finishes are done properly, so the actual maintenance cost for a 50k rifle / shotgun is under $85 / month. This is a very acceptable maintenance cost, especially provided the value of these firearms increases over time considerably.

TURNAROUND TIME:

The turnaround time depends on the size of the project and on the particularities of the project; a wood that has multiple inclusions will be harder to work with; metal that has deep rusting and pitting (especially blood rust) will require more work and will take longer than metal that has average wear but no rust or pitting marks. OUR PROMISE: As long as your firearm is in our possession, it will be treated with dignity and respect. We understand that we are trusted with family heirlooms, so we honor the firearms as part of your family history. You can be assured that for the few months that your firearm is being worked on by our staff, it will be treated like there is no other firearm like in in the world - because there isn't. There is only one firearm that your family bonded around, and one firearm that brought you those nice trophies that you are proud of. There is only one .22 rifle that your family has been teaching young boys how to shoot on. - And we are honored to become part of your family legacy.

Comments