Search Results

14 items found for ""

- The Brubaker Journal - Volume one - Issue 1 - Spring 2023

BUILDING AN AMERICAN TRADITION VOLUME ONE - ISSUE 1 SPRING 2023 I BRUBAKER ARMS MANUFACTURING, LLC Meet The People Behind Our Projects HONORING THE FAMILY LEGACY - The Story of a Litter Girl and Her Swiss Vetterli - feat. The B. Family Rifle Here at Brubaker Arms, we love being part of your family history. We are building an American tradition by preserving the history and the legacy of your family. We are an all inclusive gunsmithing / gunmaking shop, but we specialize in restoration of firearms with emotional value and high-end custom builds that are intended to be passed on to the coming generations. The Shotgun Enthusiast Corner THE SHOTGUN REPORT - A Chat About Perazzi MX2000, Perazzi MX2000S, Krieghoff and Kolar Max Lite Sporting In this article I am presenting my personal opinion regarding Perazzi MX2000, Perazzi MX2000S, with brief references to Krieghoff and Kolar Max Lite Sporting. Since we worked on a number of Perazzis recently and I was exposed to a few Krieghoffs and Kolars as well in the recent past, I thought writing an article to share some of the aspects that I wasn't aware of before might provide others with some insight as well. Perazzis are fully customizable shotguns (this is not news to anyone, I know!); from the forend to the trigger to the length of the barrel to the stock, everything can be made custom to the customer’s specs; but my comparison is based on a couple of off-the-shelf Perazzis, cut to standard size, that you would purchase from a distributor. This would be the expedited way to purchase a Perazzi. The Rifle Collector Corner THE RIFLE ACCOUNT - Firearm Restorations: What is The Correct Approach? Case Study: Japanese Arisaka When it comes to collectible firearms, there are two type of collectors. There are those who preserve firearms for their original condition, as a pristine historical object; they are called "historical collectors". These collectors are included in the Italian school of thinking - which also includes pottery collectors, architecture restorers, porcelain doll collectors, car collectors, stamp collectors, and any other type of collectors who collect items that draw their value from having been preserved in an outstanding original condition. Matching serial numbers, the firearm not having been fired, the pristine condition of wood and metal, no intervention on the firearm (like restorations, parts replacements), are all prized and increase the historical value of the firearm for these collectors. The other category of collectors are the ones affiliated to the German school of thinking - these are the so-called "typology collectors" who value items based on the design itself. The Work Behind The Scenes THE GUN MAKER'S GUIDE - A Quick Guide To Understanding Gunsmithing Prices and Second Hand Firearms The quotes that are provided by a gunsmithing shop are usually based on the gunsmith’s experience and careful tracking of how much time he *usually* spends on similar projects. For instance, after cleaning a few hundred rifles, a gunsmith is able to estimate what the cost for cleaning a rifle in average condition is. The rates are hourly, and the quotes are usually based on how many hours it takes to complete a project like yours on another similar firearm, in average condition. A “firearm in average condition” is a firearm that is at least field strip cleaned regularly, with no residue left inside the action to harden, and with no rust or pitting. A firearm purchased second hand, at 1/3 market value. The News NEWS FROM BRUBAKER ARMS SHOP - Perfected Traditional Colt Bluing Processes at Brubaker Arms Manufacturing Mid last year we have wrapped up almost 13 years of trial an error in re-creating the traditional Colt Bluing processes. It's been a long - and expensive! - journey. There are only 5 pages of documented technical information available pertaining to how exactly Colt was bluing his firearms, in order to obtain the distinctively clear blue color. We now offer this special charcoal bluing procedure which closely matches - or, as closely as document doubly possible – Colt’s process for their charcoal bluing. This type of bluing requires cooking all of the parts in the kiln or furnace with a particular type of charcoal and primer which is a type of oil and charcoal mix. This carbonizes and oxidizes the metal at the same time, which is what gives it that blue-black finish. As far as we're aware, Brubaker Arms Manufacturing is the only firearms facility that offers authentic Colt style charcoal bluing. There are a number of other shops that offer a more-blue-than black-hot salt bluing, but the Colt bluing is not a blue black, it's black and blue at the same time - it is hard to describe, but once you see it you recognize it. There is nothing like it. Below, one of the many Colt blued pistols refinished at Brubaker Arms Manufacturing. This pistol was polished to 400 before getting the Colt charcoal bluing finish. No Photoshop on that blue! The Seasons GUN MAINTENANCE CALENDAR - What Gun Maintenance Work Should be Done in Spring? PRE-HUNTING MAINTENANCE: SPRING TURKEY GEAR - Drop in your shotgun before March 1st POST-HUNTING MAINTENANCE: ELK GEAR - Drop in your rifle between January - April BLACK BEAR - Drop in your rifle between January - April MOUNTAIN GOAT - Drop in your rifle between January - April SMALL GAME - Drop in your rifle between March - April UPLAND BIRD - Drop in your rifle between February - April COUGAR - Drop in your rifle between April - May DEER - Drop in your rifle between January - April BIG HORN - Drop in your rifle between January - April GOOSE - Drop in your rifle between March - April MOOSE - Drop in your rifle between January - April DUCK - Drop in your rifle between January - April BEST PRACTICES: Give your gunsmith enough time to work on your firearm. This prevents you from incurring rush fees. Usually, for general maintenance, a quick turnaround time is 4 weeks, an average turnaround time is 6-8 weeks. PRE-HUNTING MAINTENANCE: Drop off your firearm to your gunsmith 8 weeks before hunting season begins / hunting trip departure. If the firearm is new remember that you will need some time to break it in before leaving. POST-HUNTING MAINTENANCE: Drop off your firearm to your gunsmith as soon as you are back from your hunting trip. It is best not to postpone cleaning & basic maintenance till next season. Cleaning and malfunctions will be easier to address right after you notice them and they are fresh in your mind. FREE GUNSMITHING QUOTE Some maintenance projects can be quoted online. If you are looking to get a quote, simply fill in this for and we will be in touch soon! INVESTMENT FEASIBILITY Looking to invest in a special firearm? Let's explore the best options! Service available for conversions and specialty gun work. CUSTOM FINE SPORTING FIREARMS Pulling the trigger on a special build? Contact us for your custom classic sporting firearm needs. Brubaker Arms Manufacturing, LLC 2107 E Mead Avenue, 98903, Yakima Contact ligia@brubakerarms.com 509-367-6614 (This phone number is a landline. Please do not text this number.) Hours WALK-INS: Monday - Thursday 10am-7pm APPOINTMENTS ONLY: Fridays 10am-7pm

- Perfected Traditional Colt Bluing Processes at Brubaker Arms Manufacturing

Mid last year we have wrapped up almost 13 years of trial an error in re-creating the traditional Colt Bluing processes. It's been a long - and expensive! - journey. There are only 5 pages of documented technical information available pertaining to how exactly Colt was bluing his firearms, in order to obtain the distinctively clear blue color. We now offer this special charcoal bluing procedure which closely matches - or, as closely as document doubly possible – Colt’s process for their charcoal bluing. This type of bluing requires cooking all of the parts in the kiln or furnace with a particular type of charcoal and primer which is a type of oil and charcoal mix. This carbonizes and oxidizes the metal at the same time, which is what gives it that blue-black finish. As far as we're aware, Brubaker Arms Manufacturing is the only firearms facility that offers authentic Colt style charcoal bluing. There are a number of other shops that offer a more-blue-than black-hot salt bluing, but the Colt bluing is not a blue black, it's black and blue at the same time - it is hard to describe, but once you see it you recognize it. There is nothing like it. Below, one of the many Colt blued pistols refinished at Brubaker Arms Manufacturing. This pistol was polished to 400 before getting the Colt charcoal bluing finish. No Photoshop on that blue!

- A Quick Guide To Understanding Gunsmithing Prices and Second Hand Firearms

The quotes that are provided by a gunsmithing shop are usually based on the gunsmith’s experience and careful tracking of how much time he *usually* spends on similar projects. For instance, after cleaning a few hundred rifles, a gunsmith is able to estimate what the cost for cleaning a rifle in average condition is. The rates are hourly, and the quotes are usually based on how many hours it takes to complete a project like yours on another similar firearm, in average condition. A “firearm in average condition” is a firearm that is at least field strip cleaned regularly, with no residue left inside the action to harden, and with no rust or pitting. A common mistake is to purchase - for a waaaay too reasonable cost - a firearm that had not been looked after, and assume that the gunsmithing cost for cleaning it up will be the same as for a firearm in “average condition”. A firearm that costs $1000 on today’s market will need at least the same investment in cleaning it up and bringing it to functioning order. Not all good deals are actually good deals. Firearms that have not been looked after often come with bent consumables, frozen screws, softened springs, rust / pitting and residual powder deposits which can cause binding between parts, feeding issues and a myriad of additional problems. In the pictures below, we will present a case in which the buyer spent 1/3 of the market cost on the rifle and then just about as much on getting it diagnosed, swapping a few parts and getting it cleaned up. A quick look on the Guns International “sold” section will reveal the real cost of the firearm, and if the cost of the firearm that you are interested in purchasing is too good to be true, prepare yourself to invest just about as much in addressing the firearm’s issues. Altogether, our customer made a 35% profit, which is not bad at all; but if you are looking for an economical firearm and don’t wish to make an investment in diagnostic cleaning (DCOA), be aware that a firearm sold at 1/3 of the market cost might not be as economical as it seems. This particular firearm’s diagnostic was: - Firearm was particularly dirty; - Extractor was worn out - needed replacement; detent and spring needed replacement as well; - There was a considerable amount of bur built up inside bolt body, causing binding on bolt head; - Bore showed some sign of wear but at the date of the inspection was still shiny with sharp rifling – which is why a good clean up was worth it; - Everything except extractor, detent and spring, looked good. Our shop ordered and fitted the right parts, polished the bur build up, and diagnosed and cleaned up the rifle. However, when a firearm is being brought in to the gunsmith, all that a gunsmith can do is let the customer know what are the AVERAGE prices for cleaning up an AVERAGE rifle. There is no way to say what is *really* going on inside until the firearm is opened up. This is why, gunsmiths with enough experience know to always quote hourly rates and to make sure the customers know that the rough estimates do not represent the final bill. A few factors that contribute to the increase or decrease of the costs are suggested below. In our practice, we have learned that when these conditions are met, the customer is best informed and the shop is comfortable to carry on with the project. 1. Tell the truth about what the issue is with the firearm. Here are a few statistics that will – maybe – shock those with good practices: almost 25% of gunsmith’s customers don’t tell the truth about what happened to their firearm. Why is this?, you might wonder. We assume some people do not actually know the truth, others are ashamed to recognize it, others have forgotten – this happens especially with firearms that have been sitting for a while. 2. Don’t abuse your firearm. 35% of the firearms that cross through the average gunsmithing shop’s doors have been abused either by their owner of by a friend of the owner. Tinkering with the firearm is great, but if something doesn’t go back in easily, it means that something else is not fitted as it should or it is not installed properly. 3. Understand how price lists and quotes work. Price lists are usually guidelines for average projects. The type of firearm that someone carries might be radically different than the next guy’s firearm, and the same deep clean might mean 2-3 hours for one firearm and might mean ½ hour for the other person’s firearm. There are also brands that are simply not designed to be worked on, but the entire firearm is a consumable firearm – like Llamas, Taurus, Raven, etc. They are very affordable because once they stop working they can be replaced, not fixed. Then, there are also firearms for which there is simply no technical information out there; they might actually be great firearms, even curios and antiques, but they will take more time to work on because they need to be figured out rather than simply assembled. A gunsmith’s favorite firearm is not usually based on looks or personalization, but on how easy it is to work on and how forgiving the firearm is.

- Firearm Restorations: What is The Correct Approach? Case Study: Japanese Arisaka

When it comes to collectible firearms, there are two type of collectors. There are those who preserve firearms for their original condition, as a pristine historical object; they are called "historical collectors". These collectors are included in the Italian school of thinking - which also includes pottery collectors, architecture restorers, porcelain doll collectors, car collectors, stamp collectors, and any other type of collectors who collect items that draw their value from having been preserved in an outstanding original condition. Matching serial numbers, the firearm not having been fired, the pristine condition of wood and metal, no intervention on the firearm (like restorations, parts replacements), are all prized and increase the historical value of the firearm for these collectors. The other category of collectors are the ones affiliated to the German school of thinking - these are the so-called "typology collectors" who value items based on the design itself. These collectors can also be found in any field - architecture, pottery, porcelain dolls, silverware, etc. When it comes to firearms, they are interested in preserving a firearm specimen that is supposed to be completely functional and kept in an outstanding finished condition, restored to the original condition or better. Serial numbers matching and preserving the original state of the item does not matter - what matters is the functionality of the item, as it was intended, as a reflection of the particular time in history when the item was designed. In this scenario, the primary goal of the collector will be to have the firearm functional even though - for example - at one point the barrel needed replacement. As far as the integrity of the design goes, as long as the firearm is fully functional, the item is collectible.* Note that the common denominator of the two schools of thinking is honesty in preservation: either by preserving the original historical value of the item 100% intact (Italians) or by preserving the typology of the item 100% intact and functional (Germans). Most firearms that are left from one generation to another, the so-called family guns, have seen quite a bit of use. Many firearms that have been inherited have been repaired throughout time, they have had small parts or large components changed. Firearms in original condition that have never been fired, stored and preserved in optimal conditions usually come with a certificate of authenticity which very often will be obtained by the historical collectors who will need these certificates in order to insure these firearms as they sometimes cost more than a car. But the average firearm left from one generation to another is more fitted to be collected along the German school of thinking - and restoring it to "better than original condition" will increase the value of the firearm. This is why the best way to decide how to preserve a firearm is usually by analysing the firearm, learning everything that is to learn about that particular specimen, and come up with a conclusion. What we don't often recommend is investing in a firearm in order to have it restored to the aged look - and this is where gun collectors have the edge over the gun owners, merely by having access to accurate information and taking the right decision about their firearms. A firearm that is to be restored, having little to no value for historical collectors, obtains a higher value for typology collectors and those preserving a family legacy after being restored to better than original condition. "Better than original" condition means that the entire metalwork is polished, any pitting and rust removed, and the original machining marks are removed. The original machining marks are way shallower in depth than scratches, rust and pitting, so it would be impossible to remove rust and pitting without removing the machining marks. This also increases the durability of the restoration and continued longevity of the firearm, as the finer the metal is polished, the better corrosion resistance it has, as there are no machining marks or pits or scratches to trap the dirt and moisture. JAPANESE ARISAKA CASE STUDY In the last 3 years, we have seen an increase in the number of Arisakas on the American market. They often come through the shop completely coated in Cosmoline. We recently had another Arisaka come in the shop for an assessment, which is what inspired this article. The Arisaka rifle (Japanese: 有坂銃, romanized: Arisaka-jū) is a family of Japanese military bolt-action service rifles, which were produced and used since approximately 1897, when it replaced the Murata rifle (村田銃, Murata-jū) family, until the end of World War II in 1945. The most common models include the Type 38 chambered for the 6.5×50mmSR Type 38 cartridge, and the Type 99 chambered for the 7.7×58mm Type 99 cartridge, which is comparable in power to a modern .308 Winchester round. Cosmoline is a common class of brown, wax-like petroleum-based corrosion inhibitors. The Cosmoline usually used on firearms conforms to United States Military Standard MIL-C-11796C Class 3. They are viscous when freshly applied, have a slight fluorescence, and solidify over time with exposure to air. The main ingredient in Cosmoline is aliphatic petroleum solvent, which is volatile and evaporates over time. When applied on firearms, this Cosmoline is not only brushed on, but applied in abundance, as a thick coat. This is why cleaning up the firearm of Cosmoline can be a meticulous and time-consuming endeavor, but especially when the firearm coated in Cosmoline is a family firearm, it is time well spent. In spite their exotic origin and catchy names, Arisakas rifles do not come at a particularly high value. Arisakas in general are not particularly sought for by collectors. However, in order to be collectibles - in terms of what the general population understands in the States about "collectible items", they need to be in a particularly well preserved state, have all their numbers matching and currently the Chrysanthemum stamp present on the receiver. Even if collected for their historical value, Arisakas are not particularly valuable. Collecting Arisakas for the design and typology is a good choice for now, when the rifles are available in abundance and one day they might be almost extinct. The operations that we often see done on Arisakas when being restored, are reversing the sporterized stock to an original stock. Refinishing the metal, refinishing the wood, and addressing the mechanical issues, if present. When preserving a firearm that does not have matching numbers, the most value / investment is obtained when the firearm is restored to "better than original condition". Much less return on investment is obtained when only some certain restoring operations are carried out, but not to a complete restoration. For example, a finish is applied to some components of a firearm, but not to the complete firearm. The new finish is merely mimicking the worn finish of the parts that have not been restored. The new finish is basically a “fake” old finish. When we were recently presented with an Arisaka that had its stock replaced 2 times, no Chrysanthemum stamping and no matching numbers, we needed to assess the return on investment. The condition of the metal was particularly poor, and the request was that we hot salt blue only two of the barrel bands and re-create the patina that is present on the entire firearm using the hot bluing process. There are several reasons why a request similar to the one that was made above is not financially feasible or desirable from a collector's point of view: Firstly, the firearm is of no value when it comes to a historical specimen, because some of the parts have already been replaced, the numbers don't match and the original parts are missing. The firearm had been used intensely, and the metal and wood have not been preserved well at all. Second, regarding the nature of different types of bluing, there seem to be some confusion regarding what is possible and what is not possible with different processes. The myth says that depending on when the salt bluing (also known as hot bluing or industrial bluing) process is stopped, the metal will develop a patina similar to a time-wear on it. But salt bluing does not produce patina regardless of when the process is stopped. In fact, the reason why salt bluing got a bad reputation is because the industrialists, looking to increase profits, were pulling the metal parts that were being blued out of the bluing tanks as soon as the parts had some sort of color on them, and the rusting process was being stopped before it actually had the chance to be thick enough to protect the metal. With rust bluing, there is a possibility to create a patina that can match more or less the metal of the rest of the rifle, but it is a very time consuming process and it does not contribute to placing the rifle in one of the two categories that would increase the value of the firearm - on the contrary! The Italian / historical type of collections require no refinishing of original finishes and pristine preserving from the beginning. The German / typology style requires complete refinish and mechanical functionality, not a "fake aging" finish. Remember, both schools of thinking have at the core the honesty of the item. A time-aging process reproduced at high speed through chemical processes to mimic the passing of the time is, simply put, dishonest. Dishonesty makes collectible items lose value. Last, but not least, the costs involved in "faking" time patina are way greater than the costs involved in honestly restoring the item. We went so far that we made an analysis of time and investment on the Arisaka mentioned above, with the hope that this analysis will help you make the right decision when it comes to restoring your firearm: For a couple of barrel rings to be finished with slow rust bluing and to have the time patina re-created though a technically-correct process, one is looking at around 4 hours to clean up the rings of existing rust and pittings, and then have the pittings re-created artificially. This is done because the existing, original, time-created pittings contain oil, dirt and other contaminants that would ruin the rust bluing process before even getting to the aging of the piece. No serious restorer would accept this. So all that original pitting needs to be removed, and then the appearance of pitting and patina can be created. For re-creating the pitting and building the rust unevenly to create patina, one is looking at metal prep time (about 4 hours for 2 rings) followed by a very laborious process of boiling and re-boiling the parts twice / day for 5+ days in a row. That means 1/2 hour in the morning, 1/2 hour in the evening (every 12 hours) for 5 days, a skilled gunsmith would need to work on the project. This leads to an approximate time of 8-9 hours of work. Ironically, the same amount of time (1/2 hour twice / day) would be required for dealing with the entire rifle as well (the only difference would be in the initial time needed to prepare the metal for finishing - metal polishing). This is why bluing an entire rifle is still an acceptable price, but for only a couple parts, it is not feasible. Again, this is a SLOW RUST bluing process, not a FACTORY / SALT BLUING. With factory / salt bluing, this cannot be done, because the process is different. Regarding the value of the firearm, restoring any parts of it (even just the two rings) would affect the value for Italian / historical collectors. Firearms that are valued by collectors for their historical value need to be in pristine original and unaltered condition. For this category of collectors, any refinishes or alterations will affect the value. Matching numbers are of utter importance for this kind of firearm collectors. For German / typology collectors (those who collect not for the age of the firearm, but for the type of design), firearms that are fully restored and fully functional are more valuable than firearms in original, corroded, pitted and un-functional mechanical condition. Matching numbers don't matter, because the value rests in preserving the design and functionality of the firearm, rather than keeping it a unique unaltered individual specimen. Basically, restoring only parts of a firearm would leave the firearm in between the two categories. It is better to either not restore any parts, if the firearm has matching numbers and all parts are original, or, if that is not the case, then the firearm would have way more value when restored completely rather than just partially. (*These two ways of restoring collectibles are not the only ones - especially the pottery and the architecture restoration fields have developed a few additional schools of thinking. However, when it comes to firearms preservation and restorations, these are the dominant trends and 99% of firearm cases and firearm collectors will fit in one of these categories. A good example of a black swan in restoration (that would fall under that 1% of cases) was a rifle that we recently had in for mechanical issues. The firearm presented no historical value but the client had a particularly vibrant bond with the uncle who passed on the rifle: "I don't want to wipe HIM off the firearm." In this case, the firearm had a value as a "spirit carrier" for our client, more than a historical or typology value. In cases similar to this, we recommend that some of the dings and deeper markings on the metal and wood are preserved, and not steamed completely out, so the "spirit of the ancestors" can still be seen on the firearm.)

- A Chat About Perazzi MX2000, Perazzi MX2000S,Krieghoff and Kolar Max Lite Sporting

In this article I am presenting my personal opinion regarding Perazzi MX2000, Perazzi MX2000S, with brief references to Krieghoff and Kolar Max Lite Sporting. Since we worked on a number of Perazzis recently and I was exposed to a few Krieghoffs and Kolars as well in the recent past, I thought writing an article to share some of the aspects that I wasn't aware of before might provide others with some insight as well. Perazzis are fully customizable shotguns (this is not news to anyone, I know!); from the forend to the trigger to the length of the barrel to the stock, everything can be made custom to the customer’s specs; but my comparison is based on a couple of off-the-shelf Perazzis, cut to standard size, that you would purchase from a distributor. This would be the expedited way to purchase a Perazzi. There’s also the option to pay a visit to the Perazzi factory in beautiful, sunny Italy, where people eat real mozzarella, drink real wine and come up with real designs (I wonder if there’s a connection there?). For no additional cost (other than the trip expenses), you can customize your shotgun. If you are to choose between purchasing an off-the-shelf / a second hand Perazzi or having one tailored to your needs, the trip to Italy might be worth it. The off-the-shelf MX2000 and MX2000S shotguns look very similar in terms of design and general layout. However, internally, there are some differences. As a preliminary piece of information, the MX2000S is actually an MX12 and the MX2000 is an MX8. The numbers reflect merely the grade of the action; the amount of engraving and detailing that goes into the action is what makes the MX2000 a MX2000. There are a few differences between MX12 and MX8, and we will cover some of them here – however, if you happen to have these two firearms on hand, the easiest way to notice these differences is to actually take off the stocks (only if you are familiar with the process, please!). Taking off the stocks should not be a particularly difficult task; Perazzis usually come with a large personalized screwdriver which you can use to remove the stock. (If your purchase was a second-hand firearm and it came without a screwdriver, you might be able to order one via Perazzi or purchase it as an accessory off of e-Bay.) Once the stock is off, you can easily see the internals of the shotgun exposed. The first major difference between the two firearms is that the MX12 features a fixed, non-removable trigger group and coil springs. The MX8 features a removable trigger group and leaf springs. (I need to insert a parenthesis here, from a gunsmithing shop's perspective: leaf springs are finicky, tricky little bastards. They are very elegant and look classy - and they are - but oh, dear, when it comes to replacement, they can be really challenging to find. Perazzi is obviously up and running, so their leaf springs are more readily available than leaf springs for antiques or vintage firearms. At Brubaker Arms Manufacturing, we have the capacity to manufacture obsolete firearm parts and to reverse engineer missing parts. Leaf springs are among the most sought for obsolete replacement parts. As such, we manufacture yearly quite a significant number of leaf springs for antiques - with orders from as far as Texas and the East Coast. The process of manufacturing leaf springs is quite involved; we usually start with 5-8 blanks, carefully treat the metal and bend it manually; by the time we are done with them, they are tensioned, hardened and annealed. We usually end up with 1-3 springs that we are fully satisfied with and we trust to perform well on the long run. However, leaf springs - like many obsolete firearm parts - are very finicky, and something as basic as storing the firearm incorrectly might lead to having to replace the springs again.) Another major difference is that the MX12 comes with a trigger selector as standard, which is in the safety. The MX8 does not, but it is customizable and it can have an optional barrel selector installed - which would give the trigger guard a specific and unusual shape. The MX12 has the safety and barrel selector placed at the topside lever, whereas with the standard MX8 has just the safety placed at the topside lever (lest it features the optional barrel selector). Especially with the older versions of the MX8, one must switch the topside lever to safe, slide the barrel selector to choose the first barrel (located behind the trigger) and then return the topside safety lever back to "fire". I have been informed that if one doesn’t engage the safety first, it could either break something inside the trigger, double-fire, or cause other "unknown or bad" happenings. – Never happened to me, but it seems quite commonsensical, so I would not challenge that. In comparison, the Kolar Max Lite Sporting that I liked to shoot (before foolishly parting ways with the firearm), has a roll pin through the safety selector that keeps it in "fire" position. Barrel selection is an independent lever just behind the trigger. With the Kolar, you can lock both the barrel selector and the safety. In my opinion, neither is needed in a pure competition gun, hence my Kolar has been locked; you might be interested in this option, if your shooting style is similar to mine: the bottom barrel always fires first and the safety is off. A gunmaker / gunsmith should be able to help you with this, if you ever choose to lock your Kolar. But as a general idea, the way to lock the safety on a Kolar so that it can't be pushed on to engage the safety feature is inside the action. (With the safety off, a roll pin is inserted to keep the safety in the fire position. Do not try this at home, though. Please take your shotgun to a gunsmith.) Back to our Perazzis - The MX8 is the older of the two designs. This was primarily designed as a truck gun hence the lack of a barrel selector. The MX12 followed later - sometime in the 80s, which is also why it has coil springs rather than leaf springs. The triggers are absolutely excellent in both shotguns. I made a statement about the Kreighoff shotguns a while ago, regarding the outstanding quality of their triggers. Up to that point, their shotguns had the best trigger I ever shot. But having shot Perazzis, I now tend to like their triggers better – they are absolutely crisp, clean, with a perfect break. (And this time, I reserve the right to amend my statement regarding my top trigger preferences, as I have not exhausted my “shotguns to shoot before I die” bucket list!) (This being said, when it comes to engraving, if you are enamored by the clean and precise German line & artistic motifs – like I am - your expectations will not fall short when you go with a Kreighoff. There’s just something magical about the simplicity and depth of the German embroidery, lace work and engraving patterns, in my opinion.) Regarding other differences between the standard Perazzi MX12 and MX8, is that you can remove the complete trigger group on the MX8; the removable trigger group is significantly wider than the non-removable one. So the stock is a little bit more consistent around the trigger group area on the MX12 (non-removable) than on the MX8, where the wood is carved a little bit more to fit the wider removable trigger group. The practical side of removing the trigger group on the MX8 is that it is a fairly easy process; you can do it by pushing the safety forward (push hard) and then the trigger slides out really smoothly and reveals what I would call – from a gunsmith’s perspective - quite a complex and compact work of art. You can see the hammers powered by the springs, the sear and obviously, if your shotgun comes with the optional barrel selector, you will also see that. The hammers have different angled faces on them which meet the firing pins which obviously go to the top and bottom barrel. The great advantage of having a completely removable trigger group is that you can easily replace your current trigger group with the one that you casually carry with you as a spare trigger group on the fly - and feel no difference in the gun. Last but not least, a small comment on the mechanical aspect of these two Perazzis, which is something to really look at, from our perspective. These Perazzi firearms feature very, very thick, very strong action fences where the drawers are machined into the side behind the jointing stub pins. The lump has a couple of recesses that these two drawers lock up into, and they give an incredibly strong lock up on the gun. The actual locking itself is carried out by two H pins that visibly protrude in the action (also often called a locking block); it is a really strong system. The design is so smart because it manages to feature thick enough machined metal locks to yield a strong bond, without sacrificing the elegant look. When you look at an equivalent, say DT 11 or even a Krieghoff, you can notice that these companies have been, historically, on a real “tour de force” in engineering and designing different ways in which their shotguns would be strong but also elegant and nimble. When looking from the outside, neither one of these firearms show exactly just how strong the lock is, as they all feature typically beautiful European design elements. Perazzi MX8 Perazzi MX12

- HONORING THE FAMILY LEGACY: The Story of a Litter Girl and Her Swiss Vetterli - The B. Family Rifle

Here at Brubaker Arms, we love being part of your family history. We are building an American tradition by preserving the history and the legacy of your family. We are an all inclusive gunsmithing / gunmaking shop, but we specialize in restoration of firearms with emotional value and high-end custom builds that are intended to be passed on to the coming generations. This is the story of a little girl and her Swiss Vetterli. Once upon a time, there was a blue eyed, blond-haired all-American little girl growing up in the peaceful valley of Yakima river. When she was 5 years old, her dad was working really hard to provide for her and her family. He took on a part time job at a gas station, to help make ends meet. One day, a stranger stopped at the gas station and asked to buy gas with no money – all he had was a Swiss Vetterli that he could trade for gas. The man accepted the trade. When he got home, the bond haired, blue eyed 5 years old girl fell in love with the gun that was taller than her! She asked her dad to give her the gun, and he promised that one day, when she’ll be a grown woman, she could have it. A few years went by, and the father forgot he promised the rifle to his daughter. His cousin saw it and wanted it. Before the gun could trade hands, the little girl interfered and stropped the transaction. – “But you promised me this gun! This is MY gun!” Time went by, the little girl turned into a young lady. When she was 21, her father passed away, but the gun stayed in the family’s possession, in the care of the mother). The little girl turned 50 one day; her mother remembered that the firearm was still not in her daughter’s name – so she finally turned over the papers and made the ownership of the firearm official. Now, the little girl is a fulfilled woman, in her prime 60’s. Her donating husband thought it would be a lovely gesture to have it restored for her. The rifle restoration took 2 ½ years and a tremendous amount of effort. But finally, today, 14th February 2023, on Valentine’s Day, the little girl who inherited this Vetterli will once again experience the joy of falling in love with it! The firearm will now be proudly displayed on the wall of their home in honor of the Father who passed on a tremendous legacy of love and support to his daughter. He will be remembered as a trustworthy man who raised a great family! Today we have a Swiss Vetterli in the works to show you. One fascinating detail about the Swiss Vetterli rifle design is that it has a tubular magazine housed in the long forehand. It’s a tube fed bolt gun, a predecessor to some of the lever types. The carrier is positioned and functions just like a lever action carrier, except that it is a bolt that operates it, not a lever. We took footage and records of this project in the condition that it came in, then again during the process of restoration and with different elements in different stages of restoration. The final footage is the after-restoration footage. We have here the barrelled action; it is still in the condition that it was brought to us so you can see that it is pretty heavily corroded. There's a good bit of pitting all over the barrel and the receiver. The buttstock has a couple cracks that need to be repaired as well as a lot of dirt and oil that in time have soaked in, around the tangs and in the other metal inlet areas. A few of the metal parts have been polished – they have actually been wire wheeled to remove the surface rust and dirt from surface. This allows you to see all the pitting that needs to be polished out. We still have a lot of pitting to deal with on these. This other set of parts is further along in the polishing process; we have removed all the pitting, all the machining marks and rust. They have been polished at #240. We're getting close to the finished results of polishing. The main part of the metal polishing, the stock restoration and the bluing are still to be done – so there's still a good bit of work to do. But it's coming along! […2 ½ years later…] Hi, this is Bryan at Brubaker Arms Manufacturing. Today we have our FINISHED Swiss Vetterli project. This gun had coat hanger shoved down the barrel by the owner's father - because the owner was still very young at the point where she received the rifle as a gift (5 years old) - in hopes that she would not attempt to shoot the gun in the condition it was in. We have removed the coat hangers, restored the inherited gun, and this is what we now have! There were several cracks on the buttstock - you can see that we still have a little divot on the side that had a deeper crack – and along here you can see small traces of the second crack repair. There were a number of parts that were hardened for one reason or another. The trigger bow, the trigger and the cap of the bolt were all hardened; they don't really need to be and so we annealed them before polishing. We were barely making a mark with with the diamond file on the hardened parts. The rest of the metal was extremely pitted - so much so that we started out with a grinder. I have never started polishing a rifle with a grinder before, but we can even get to this end result. The buttplate has been polished out, all the pits have been removed before it was really re-blued. If you look closely, you can see this one little spot that has a slightly different color from the rest of the wood. There were a number of rotted patches underneath the buttplate that I had to dig out in order to bed the buttplate back in place and prevent any more deterioration of the stock. We removed all that rotten wood with some epoxy and sanding dust from the stock. This thick paste mixture was used to fill in the rotten wood channels. The sanding dust from the same piece of wood preserves the color of the stock, and putting the sanding dust back into the same piece of wood allows it to take whatever kind of stain ends up being put on. We replaced the rear sling swivel just to fill the big gap in the middle that was left by the previous sling swivel. Unfortunately, we could not locate - and the budget did not allow for fabricating - a middle barrel band, which has the front sling swivel in it. As I said, we polished all the metal, all the pits; that took forever. Literally. I thought Jesus was going to come back before we were done. (Fortunately He did not, so we got to finish the rifle - But anytime you're ready, Lord, please do come.) So we have this beautiful piece of wood now - as I said, we polish everything, including the wood. The wood was atrocious; if you have watched this whole video you'll see the before footage. It took a number of whitening sessions for the wood, bleaching it to get all of the grime oil out of it. But we were able to stain it in this beautiful color, that just matches it so well!

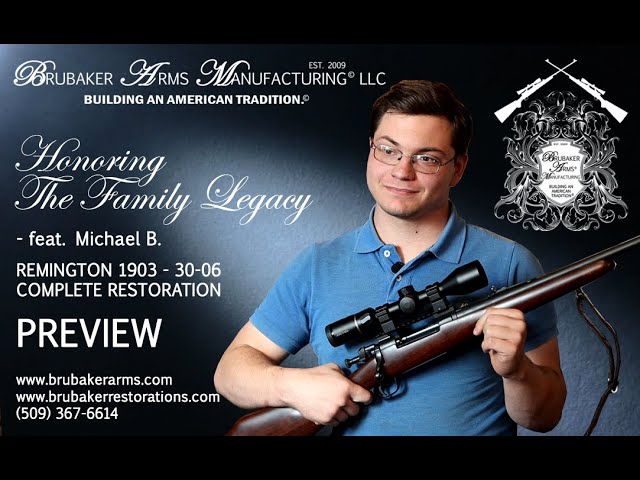

- HONORING THE FAMILY LEGACY: Remington 1903 30-06 Full Restoration - feat. Michael B.

Today we have a Remington-made 03 – or a Remington made Springfield 1903 – since everybody calls it Springfield 0383; is the same thing. This one happened to be manufactured by Remington, because everybody was tooling up for World War One. So this is a nice old gun. When it came in to us, this is the original stock. It had a pistol grip (we'll have some before pictures in the footage), and this is the end result! The stock was modified to the client's specifications, including changing the pistol grip to a straight grip and removing the black forend tip and replacing it with a matching forend tip - and we think we did a pretty good job matching that color. We did a total restoration of the stock, we steamed out any of the dings and dents and any other marks that might have been in it before giving it a fine English oil finish. Once the stock got down to the final sanding we actually polish the wood itself, and that helps to bring out the figure in the wood as well as the contrasting colors. After that we seal it with our thinned oil finish that we make here in house. Our in-house made finishes do not have any drying agents in them, like the commercially prepared oil finishes. So they take a longer time to dry between applications. It's a fine English oil finish. It takes time. One would start by applying coat of oil a day until the wood won't absorb the oil and dry in a day; then a coat a week until the wood stops absorbing the oil with that frequency, and then a coat of oil per month until the wood stops absorbing the oil - and it eventually dries entirely. The finish will be soft in the final stages of settling, but it will eventually harden. That way one can build up quite a “shell of oil” over the wood just to protect it. But at the same time that oil finish really catches the light and really draws out the figure in the wood. This finish is certainly our best finish. We kept the original front sight (a banded front sight ramp). We pulled it off, bored out the band so we could slide it back a little bit in order to thread the muzzle for our BAMF Muzzle Break (our sporturized model). The scope has a one piece zero MOA Picatinny mount with quick release springs. The metal was polished by hand to remove any of the pits and marks before we did a final bead blast and then we blue finished the rifle. We also installed a fresh recoil pad. KICK-EEZ is definitely the way to go. And this is the original sling. It was important to our client to maintain the original sling so we found a leathersmith who could actually put a backing on, and now it looks great and it can be used for a long while. Watch further to learn this firearm's sentimental value for our client. STATIONED IN WASHINGTON STATE, YAKIMA VALLEY - SERVING NATIONWIDE Brubaker Arms offers the finest of custom made firearms. Built from scratch - not only personalized - our firearms rank high end in exhibitions and among connoisseurs. We stand behind our services offering maintenance, gunsmithing and general repairs for our custom built firearms and any other brand available on the market. Whether you are inquiring about your custom made firearm, need restoration services for your antique firearm or work on the newest model available on the market, we at Brubaker Arms will exceed your expectations! Find out more at: www.brubakerrestorations.com www.brubakerarms.com

- Honoring The Family Legacy: Harrington & Richardson (H&R) 300 Mauser Action 308 Win

Today we have a Mauser action manufactured by Harrington & Richardson (H&R) 300 Mauser Action 308 Win chamber to 308 Winchester. The client brought it in because the stock had a small crack at the back of the tang of the action. He was looking to have that repaired. It seemed to be more of a cosmetic issue than a structural one. Upon further investigation, we found out that the crack was not just at the back of the tank but ran from the right side of the chamber all the way down through the action and into the wrist of the stock. So we cleaned it up and initially glued and clamped everything together and then bedded some wooden cross pins perpendicular to the crack to keep everything more rigid. After that, we recommended a pillar bedding for the stock just to make sure everything stayed in place. When we opened up the gun, it was apparent that the barreled action had become loose in stock and that resulted in battery, which was what caused it to crack. With a press fit pillar bedding the action cannot move in the stock. So therefore after repairing the crack and pillar bedding, we have eliminated the possibility of it occurring again. After doing that work we refinished the outside of the stock, stripped off the old finish and did a clean up sanding on the wood, polished it to bring out the figure a little bit and then put on a spray varnish finish. In this video, we familiarize our audience with the type of restoration work that we do here at Brubaker Arms Manufacturing, Restoration Department.

- HONORING THE FAMILY LEGACY: Winchester M88 Stock Restoration - feat. The Jaussaud Family

Today we have a Winchester Model 88 lever action, .308 Winchester, and it came in for a stock restoration. The stock was in pretty rough shape when it came in. It had some dings in it and a lot of the original varnish was worn off. It wasn't quite this colour, the wood had a lighter stain on it. The recoil pad had a really poor fit so we cleaned that up as well. We stripped the stock of all of his old finish, steamed out the dents that were there. We did a light sanding of the finish then we stained the stock with a dark black walnut American walnut color, as that's what the client was looking for. We then we put a fine English oil finish on it. We make our fine English oil finish blends here in house. We start with raw linseed oil and cook it to the temperature, the consistency and the color that we want. Making it here allows us to add different additives. That way, we can control color content and quality of finish way better. Finishing a stock with a natural oil, that does not have hardening agents in – like the commercially prepared oil, does take a little bit longer than applying a commercially available oil finish. But we think the results are worth it. This oil has a shine and lustre that you can't get with a commercially available finish. We did not restore the bluing on this rifle, but we might just get to do that soon... Watch further to learn the story of how this firearm came to be our customer’s possession. STATIONED IN WASHINGTON STATE, YAKIMA VALLEY - SERVING NATIONWIDE Brubaker Arms offers the finest of custom made firearms. Built from scratch - not only personalized - our firearms rank high end in exhibitions and among connoisseurs. We stand behind our services offering maintenance, gunsmithing and general repairs for our custom built firearms and any other brand available on the market. Whether you are inquiring about your custom made firearm, need restoration services for your antique firearm or work on the newest model available on the market, we at Brubaker Arms will exceed your expectations! Find out more at: www.brubakerrestorations.com www.brubakerarms.com

- SACRED GEOMETRY IN GUN FITTING

Sacred Geometry and its Fields of Application When I studied Architecture back in Europe – before moving to the States – I had no idea that sacred geometry is so prevalent in harmonious gun stock design. But after a few years of assisting Bryan in designing very custom gun stocks, I started asking myself: “Why do we like this shape for this custom gun stock, and why does the other shape – which is still accurate number wise – simply not work visually?” I started sketching custom gun stocks and drawing patterns on them; just the same way I studied, for example, the Pantheon, back in university. I used to study the facades of old Italian villas or Roman temples by drawing force lines on the facades. In architecture, a force line represents graphically the internal force acting within a building across imaginary internal surfaces. The force lines show the maximal internal forces and their directions. The closer it gets to the golden ratio and the more it respects the existing force lines of the plot that it is built on, the more pleasing a building becomes to our eyes, although we have no idea why that is. Practically, the force lines focus our eyes towards the focal point and produce an aesthetically pleasant experience as they guide our brain to the elements of a building in a particular succession of images that create a pleasant aesthetical experience. Mastering the study of force lines in art and architecture is something that can take years of study. My extensive background as an architect provided me with a pair of lenses that helped me recognize sacred geometry principles in custom gun stocks. This is really fascinating, because it means that whatever mesmerized humanity for ages about the Pantheon is what still mesmerizes us today when we admire a well-balanced and properly fitted and designed gun stock. After studying a few of these phenomenally looking gun stocks that Bryan designed for the customers and that fit them properly and are a joy to look at, I started noticing that there is a particular harmony in lines that is very pleasant to my eyes, that I can’t put my fingers on, but surely, it is there. So I started sketching these force lines on our gun stock designs, and then I realized that all pleasing curves of the gun stock, regardless how curved or crooked it was, had elements of the golden spiral in them. In geometry, a golden spiral is a logarithmic spiral whose growth factor is φ, the golden ratio. That is, a golden spiral gets wider (or further from its origin) by a factor of φ for every quarter turn it makes. So I started thinking about how architecture and firearms have actually influenced each other tremendously throughout the history. I discovered with surprise that gunmaking and architecture actually share a fundamental connection that is, as far as I have experienced - obscured both from European Architect’s understanding and from the American gunmaker’s understanding. As a young nation, America doesn’t have a web of military architecture sprinkled across its land, which is easily accessible to the public, like Europe does. So the American gun makers genuinely missed out on experiencing the historical approach of military architecture, which was based almost exclusively on the development of the firearm industry. At the same time, in today’s modern Europe there is close to no understanding of the spirit of freedom that gives birth to firearm design and development. European Architects miss out on the opportunity to see how the aesthetic principles that they discovered in nature and applied to their masterpieces for centuries, apply to high end firearms. European Architects are taught that firearms had influenced military architecture, but studying the firearms to understand in what way they influenced Architecture is not seen as relevant. There are very few who specialize in military architecture. My specialization is a Master in Architectural Restoration, which certainly includes military architecture, but it does not exclusively focus on it. However, my final design for the graduation exam had to do with restoring an old military Romanian defense tower that was connected underground, through a series of labyrinths, to a Serbian city. Apparently, that tower was used by the nobles occupying the village to escape in case of war a number of times. Looking back at my architectural project, I still think it was a fascinating project to work on – however, after living in the United States and doing what I do for a living now, I can certainly make the remark that during the time when I was working on this project, I had absolutely no understanding of firearms. Actually, I have never held or seen in real life, other than behind a piece of glass, in museums – any kind of firearm. In that sense, there is one architectural dialogue that I failed engaging in with that building, while designing the Restoration proposal for it. I wonder what that tower would have had to say about the firearm industry at that time, if I would have known enough to ask those bricks and stones the right questions. But after studying Bryan’s stocks, I realized that they all respect the golden ration or somehow their curves resemble the golden spiral curves. And I decided to share this exciting discovery with you, because if we know that any custom stock will necessarily follow the golden ratio, it is easier for the gunmaker to master the shape of a new design. At the same time, since a great number of firearm antiques are commercialized online, it helps antique firearm collectors determine if the image they are looking at is the image of the original stock (or a quality replica), or it is a poor aftermarket stock that was slapped on a fine firearm. Furthermore, understanding the amount of science and skill that go into designing a custom stock and the amazing results of a project like this, will help the customer understand the length of time needed to produce a one-off stock and the price tag that it comes with. Specialized stock fitting – why bother? Off-peg-guns are intended to suit the average shooter with an average build and height. In a sense, they are very much like the “one size fits all” Walmart clothing or the diet recipes that are supposed to work for everyone but don’t. In addition to not all of us sharing the same size, length of pool, and style of shooting, a high percentage of population is cross eyed dominant. Approximately 69.42% of the population is right-eye dominant and 29% left-eye dominant, with 1.58% of the population with no dominance. People with cross eye dominance do best shooting the unusual “crooked stock”, especially if the eye dominance is not a matter of habit but a matter of strabismus. If people are naturally left handed and left eye dominant, a left handed stock should fix the issue; if the eye dominance is opposite to the hand dominance, left eye dominant people can still learn to shoot with the right eye – they can somehow get used to it in most cases. If the reason for cross eye dominance is strabismus, people generally need to use a “crooked” stock. This is a good video explanation of how crippled or crooked gun stocks came to be: https://www.youtube.com/watch?v=_mcVFrk7omk Gun fitting is more complex than merely making sure the stock is long or short enough. It has to do with the entire physiology of the shooter. Since we possess bodies with natural shapes, regardless how “off” our body proportions are – or how well-proportioned we are – the numbers pulled off a body will still follow the golden ratio and the golden rule that we find in sacred geometry, because God / nature don’t know how to not be natural. A person with long limbs will very rarely have the torso of a kid (unless a dramatic accident happened), and a tall person will rarely have tiny T-rex arms (*please pause and imagine a T-rex shooting a rifle*). Gun fitting takes in account the shape of the cheek, the shape of the shoulder pocket, the length of pool, the position of the grip, and eye dominance. In other words, gun fitting has to do with designing a tool that is most suitable for your whole body and how you carry yourself. As a consequence, we discovered that a properly fitted gun stock will necessarily have to respect the golden ratios, since it is designed to fit a human body which is respecting the golden ratio. There are a great number of studies written by architects and aestheticists, on the topic of the golden ratio in the human body, so I will not insist on this aspect. Enough to say that we are so certain that the human body respects the golden ratio, regardless how tall or short or crooked the body is, that Ernst Neufert (15 March 1900 – 23 February 1986), who was a German architect (assistant of the famous Walter Gropius) developed an entire system of architectural design based on the golden ratio found in the human body. Not to mention, Michelangelo had dabbled intensely in studying the proportions of the human body, and left behind an abundance of information that was used as foundation for Neufert’s work. If a gun fits well, then the shooting is more likely to be fluid and accurate. If it’s wrong, then the gun won’t point exactly where you want it to and your shooting may look tight and ‘snatchy’. Furthermore a badly fitting gun may cause bruising under the shooter’s cheek, on the jawbone, shoulder and forearm. It can also cause injuries to the index finger from the trigger guard. Gun Fitting Process The process of designing a custom made stock is quite lengthy. There are a few stages that we have determined (and this process is actually very similar to the process of designing a building.): 1. The Feasibility Study During this process, the shooter’s body is measured, the intended use of the firearm that the stock is made for is clarified and the costs involved are narrowed down as much as possible. This might be seen as a tedious process, but it is fundamental when it comes to evaluating the projected success of the endeavor. During the feasibility study of the custom gun stock, it might become clear that the investment is not justified for the intended use of the firearm. Or, on the contrary, the feasibility study might reveal that a few more hours of work invested in the stock might increase the accuracy and the fluidity of the shooting so much that the investment is worth the time and money. Designing custom stocks has a lot to do with the physiology of the owner. The face shape, the shoulders shape and broadness, neck length, overall height, arm length, style of shooting and type of shooting (competition, defense, hunting), all these factors influence the shape of the stock. A good gunmaker will – probably more instinctively rather than consciously - know how to apply the golden ratio principles to the stock build. We, at Brubaker Arms, tend to think that this is more of an instinctive knowledge that gunmakers (who are highly crafty and artistically inclined) possess naturally - rather than a conscious applied knowledge; no one on our team has ever heard any gun maker mentioning the golden rules in stock design, yet we discovered that Bryan had always applied these ratios in his designs, without being aware of it. This instinctive know-how might be one of the naturally possessed (or not possessed) skills that make the difference between a good gunmaker and an amateur who can’t find the shapes that make a stock high end. What we know for sure is that in all high-end firearms we designed or consequently looked at, after designing these ratios in our designs, respect the Golden Ratio. When it comes to the way the lines flow, the scroll patterns that are to be engraved on the metal or the checkering patterns – all structural and decorative elements – will respect the Golden Ratio, the perspective effect and the Golden Spiral principles (all discovered by architects). Producing standard stocks that look harmonious is not a big problem, because the stock needs to respect only the golden proportions as there is no shooter to match the stock to. But when the size of the stock and the multi-dimensional aspect of the physiology of the shooter are thrown in the mix, designing a harmonious stock can be a challenge. The Feasibility Study can vary between 5-10 hours of work at the bench, depending on how uncommon the measurements of the shooter are. 2. Making The Pattern The Pattern is a first 3D sketch of the stock. There are gunmakes who skip this stage, because making a pattern will take about 15-20 hours of labor intensive work. During this stage, the stock design that was sketched on paper will be executed manually on an appropriate piece of low end wood blank. The purpose for making a pattern is trifold. First, it offers the possibility for the gunmaker to make as many modifications as needed. Fine tuning the stock might involve adding gyps build-up on some areas or shaving off a hair. Doing this fine tuning on the final stock is impossible. Second, the pattern can be taken out and used until the customer feels comfortable with it. Sometimes, especially in situations where the stocks need to accommodate for particularly uncommon physiques, the customer will be unable to say if the stock fits him right or if there are any changes that need to be made. Small changes might make a massive difference. Third, the pattern can be saved for further projects. Provided the customer will not go through any significant body changes, one pattern is enough to keep for as many future projects as needed. For this reason, custom stocks are recommended only after the shooters are done growing – teens will need to wait. 3. Duplicating The Pattern Once the pattern is done, it will be duplicated in the real piece of wood. If the design is particularly personalized, with very particular shapes, it will require quite a bit of hand carving, as machine carving will not be enough to replicate the pattern. During this time, the firearm is usually left with the gunmaker, so the fitting can be done extremely carefully. Duplicating and finishing the pattern to the point where the only things left are applying the finish and the cutting the checkering will take 80-100 hours of skilled, labor intensive work – again, depending on how uncommon the stock is. 4. Finishing and Decorating the Stock Finishing and decorating the stock is the last stage – and probably the most nerve wracking part – of stock fitting. This is because at this stage, any scratch, any temperature variation and any tool-drop will leave marks that are hard to recover from. The stock needs to have the blend of oils or the varnish put on at particular temperatures for best results, and definitely not in the high or low temperatures, in order to avoid disasters. This process can take up to 50 hours, depending on just how complicated the checkering is and the wood’s level of absorption. Case Study - Winchester 1873 What led to this analysis of the force lines and ratios in stock design was a very particular study that we did on a Winchester 1873, for a competition shooter. This lady is already a highly capable action shooter competitor; she is often coming home with prizes and honors. However, she is using a fun little Winchester 1873 with a standard stock, which is definitely not fitted for her. Her physique is very unique; her frame is petite and what stands out about her face is the really high cheek bones. So in addition to shortening the stock, when we pulled the numbers off her, this is what we came up with: Length adjustment: - LOG: 4” - LOP: 12” Shape Alterations: - Really high cheekbones - lift comb with 1’’ above current level - Lower bottom of heel with 1 ½’’ - Lower comb (top of heel) with 2’’ - Toe out – rotate at 7° - Cast off – ¼’’ Minimum stock size required – needs to be over-sized quite a bit: - Minimum length 16" - Minimum height 9" - Minimum thickness 2 1/4" You might realize, looking at these numbers, that they indicate a really interesting shape. So we sat down at the drafting table and drafted for a great number of hours, until we ended up with an over-exaggerated hog back design – which we named the “angel wing” – because it literally looks like an angel wing! While designing this, we were both looking at the numbers and the shape was simply not pleasing. Bryan locked himself in his office and came out once every hour or so with a sketch: “Does this look right to you?” “No. It’s bulky here.” – or, “The lines don’t flow well here.” Until the end of the day, when he came in the main office with this beautiful angel wing: After the design was ready, I scanned it and inserted it in the CAD design software that we use in the office and realized that even with this particularly unique stock, the design became pleasing to our eyes when it reached the point where every line was emulating the Golden Spiral. Stock design is not only about numbers, it’s about the numbers recreating the negative image of the human body – and doing this while looking appealing to the eye. Negative space is the space within, between, and around objects. In sketching, negative spaces are actual shapes that share edges (at least partially) with the positive shape -- the object or objects you are drawing or painting -- thereby creating the outline of your subject. Every positive shape is surrounded by negative space. Gunfitting is about filling in that space between the cheeks, the pocket shoulder and the tip of the barrel with the most suitably shaped stock that will reduce to 0 seconds the time required to adjust the point of aim. When a fitted stock is thrown on the shoulder, it should fall in the right place and require no adjustment, and the shooting should be perfect. There should be no difference between the point of aim and the point of impact. The discovery of how sacred geometry can be applied in custom gun making is revolutionary for our shop, and we are certainly looking forward to applying this principle to our upcoming projects.

- How It’s Made: Firearm Restoration at Brubaker Arms Manufacturing, LLC - Restorations Department